Pulse heating and slip enhance charging of phase-change thermal batteries

TL;DR

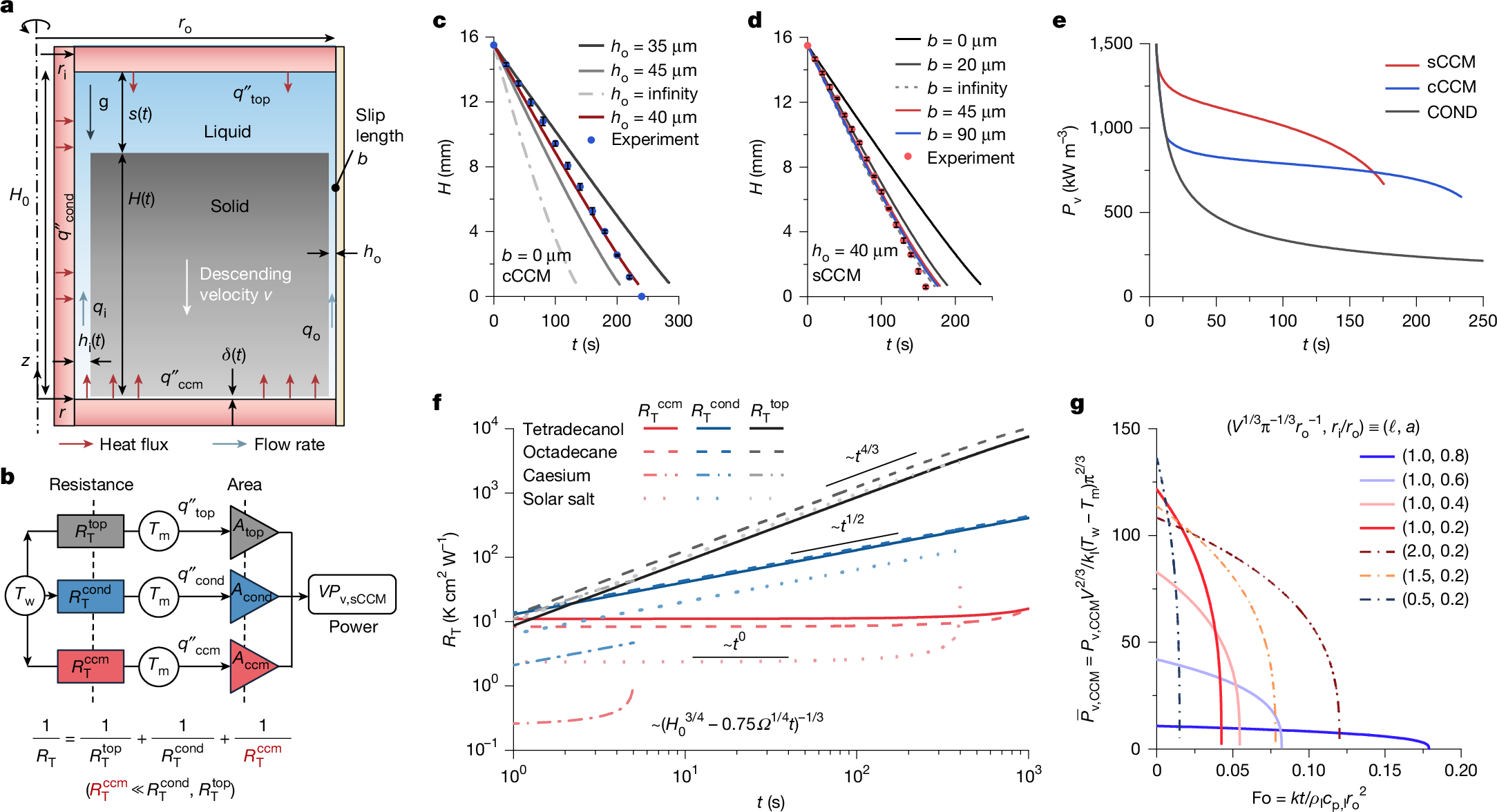

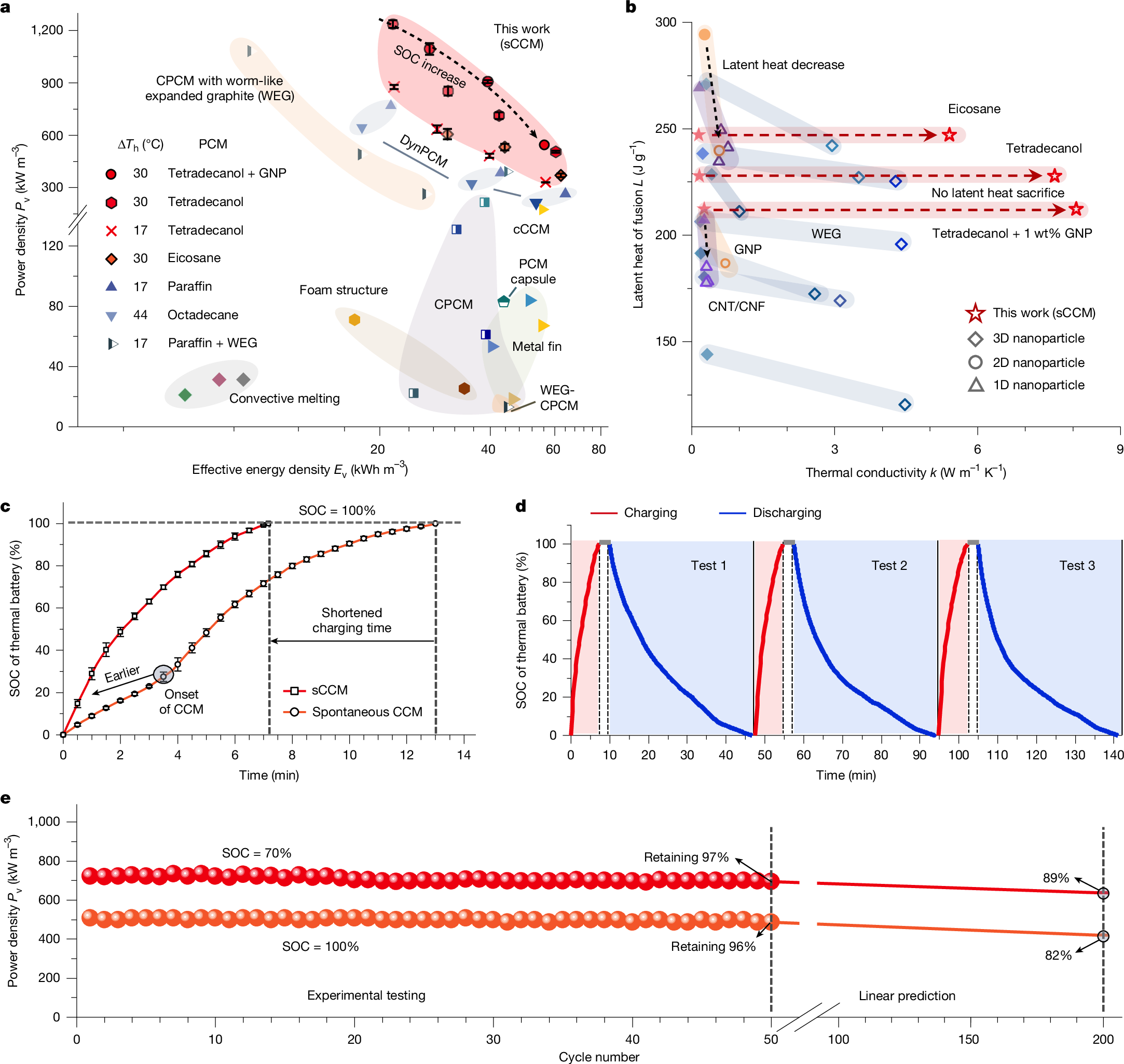

Researchers developed a slip-enhanced close-contact melting (sCCM) strategy using a composite coating to boost charging rates of phase-change thermal batteries without sacrificing energy density. This method achieves a record-high power density of 1,100 kW m⁻³ and is adaptable to various PCMs for efficient thermal energy storage.

Key Takeaways

- •A slip-enhanced close-contact melting (sCCM) strategy enables fast charging of phase-change thermal batteries without energy density loss.

- •The design uses a pulse-heated layer to initiate melting and a slip surface to sustain sCCM, achieving a power density of 1,100 kW m⁻³.

- •This approach is generalizable to diverse phase-change materials, offering high cycling life and scalability for thermal energy storage.

Tags

Abstract

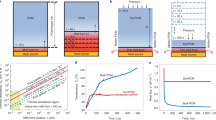

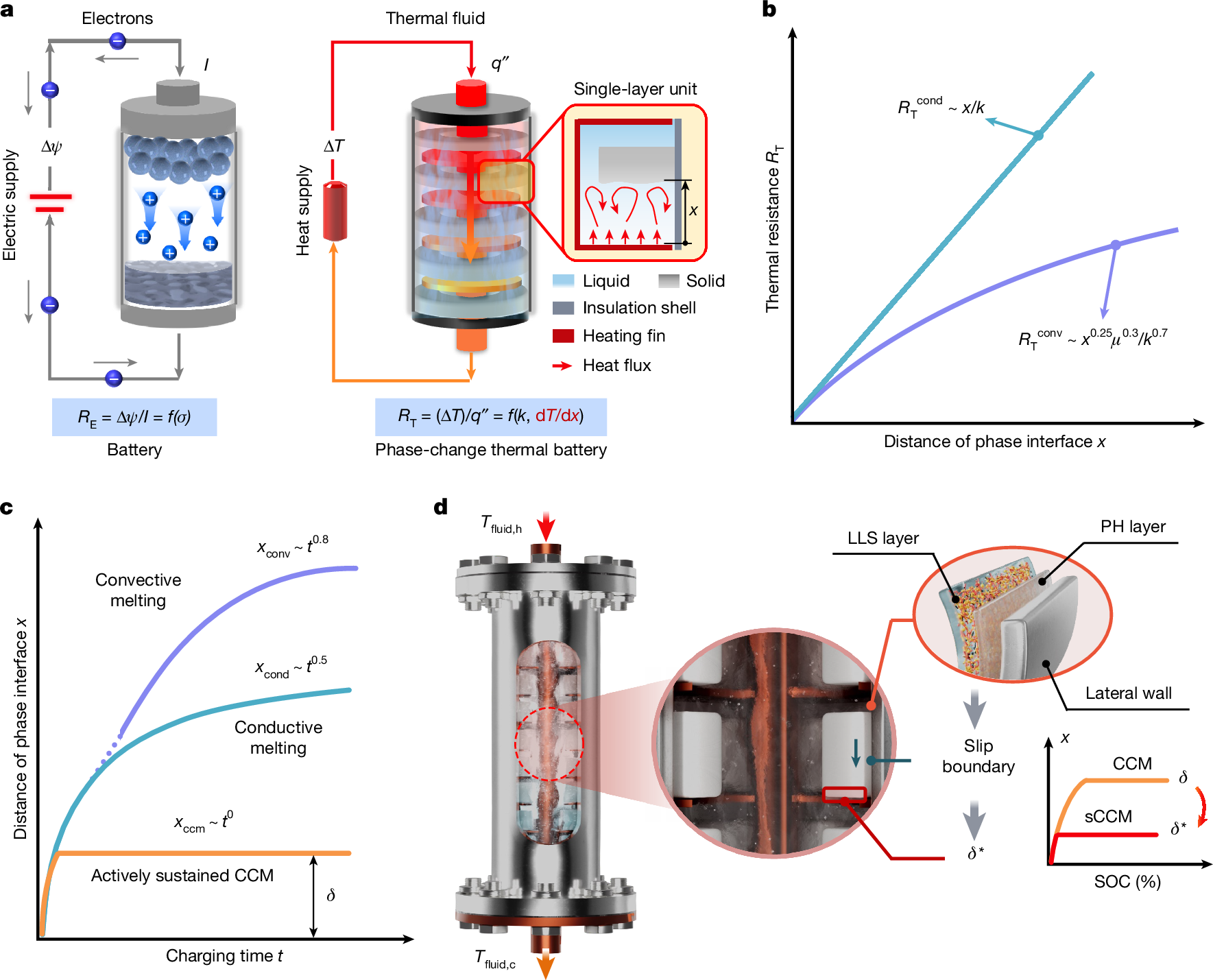

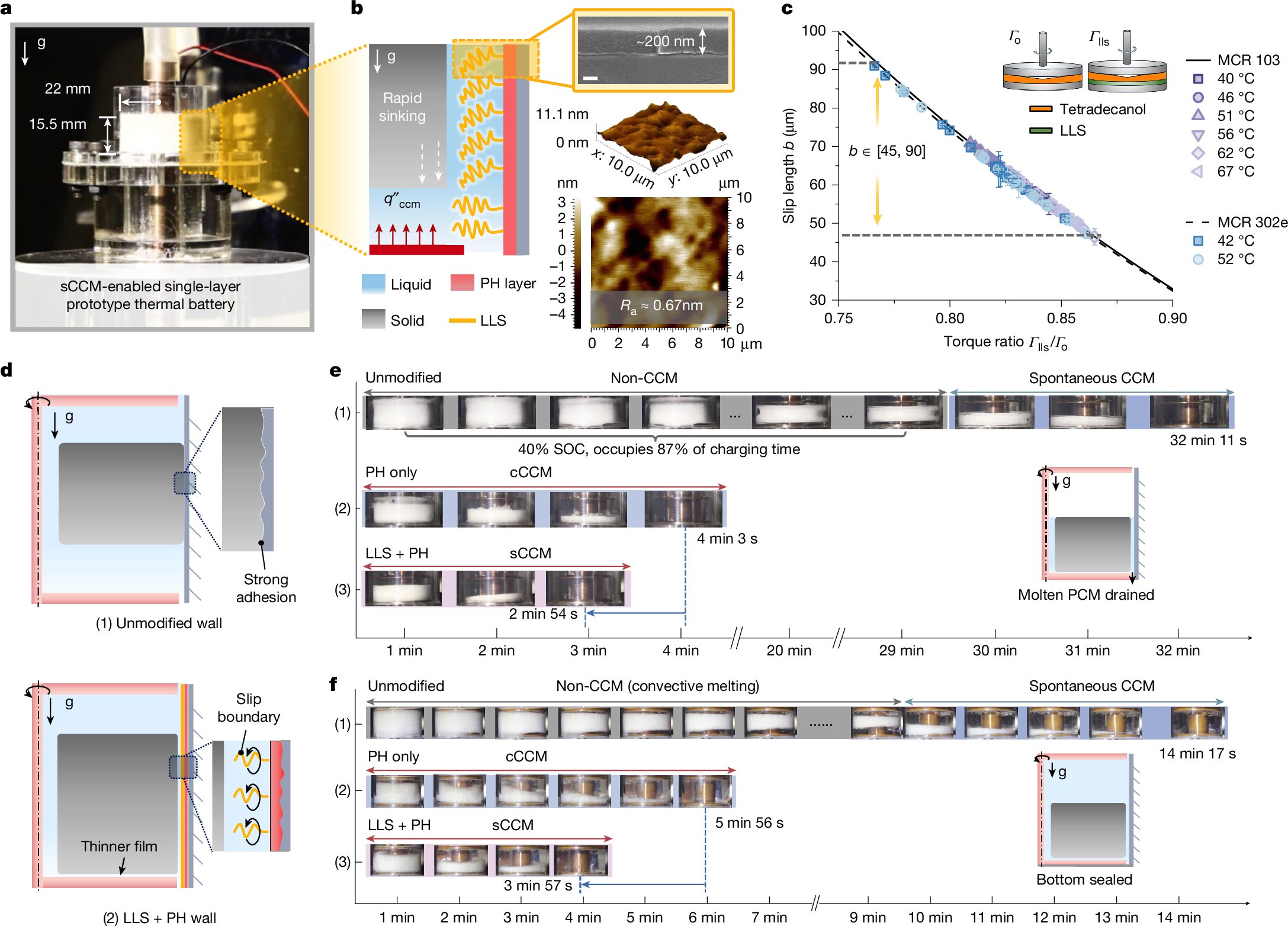

Phase-change thermal batteries for renewable energy storage and waste heat recovery demand high energy density and fast charging1,2,3,4,5, which are mutually exclusive because phase-change materials (PCMs) with high melting enthalpy are usually poor heat conductors6,7,8. The charging rate can be improved by making composite phase-change materials (CPCMs) with increased thermal conductivity9 and/or by exerting an external force to realize close-contact melting (CCM)10,11,12. However, these methods inevitably result in energy density losses and/or extra energy consumption. Here we report a strategy to boost the charging rates without sacrificing energy density, based on a rational design of a composite coating that enables slip-enhanced close-contact melting (sCCM) inside sealed thermal batteries. Using organic PCMs, we demonstrate a record-high power density of 1,100 ± 2% kW m−3 in a prototype. Our coating design integrates a pulse-heated (PH) layer that premelts the PCM to initiate CCM, together with a liquid-like slip surface that ensures unimpeded sinking of the remaining solid and sustains the sCCM mode throughout charging. We develop a model to explain how the slip surface enhances the charging rate. With high cycling life, adaptability and scalability, this strategy is generalizable to diverse PCMs, enabling high-performance thermal energy storage over a wide range of temperatures.

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Enhanced passive thermal management of lithium-ion batteries with conical cylindrical chamber incorporating various phase change materials

Experimental investigation and modelling of a laboratory-scale latent heat storage with cylindrical PCM capsules

Data availability

All data are included in the paper, the Extended Data and the Supplementary Information file. Source data that support the findings of this study are provided with this paper.

References

Chu, S. & Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 488, 294–303 (2012).

Saher, S. et al. Trimodal thermal energy storage material for renewable energy applications. Nature 636, 622–626 (2024).

Gur, I., Sawyer, K. & Prasher, R. Searching for a better thermal battery. Science 335, 1454–1455 (2012).